Commercial printing is unforgiving. Files need to follow pretty strict technical rules or things go sideways fast - missing fonts, wrong colors, transparency glitches and suddenly the output looks nothing like the original design. Standard PDFs are too flexible for this: they allow RGB sneaking in, optional font embedding, different transparency interpretations, and all sorts of surprises that print shops definitely don’t want.

This guide breaks down what makes a PDF actually print-ready for commercial printing, why PDF/X standards (X-1a, X-3, X-4) fix the most common issues, and how to export files that print reliably without production delays or those expensive re-prints.

What Makes a PDF Print-Ready?

A print-ready PDF is basically a normal PDF with less freedom and more control. It enforces technical requirements so nothing unpredictable happens once the file hits a press. Commercial printers deal with precise workflows that expect files prepared exactly to specification, and there’s little room to improvise when the job is already scheduled on the machine.

So what makes a file print-ready?

- Fonts 100% embedded: text looks the same everywhere.

- Correct color spaces: most often CMYK for presses instead of screen-only RGB sneaking in.

- High-resolution images: 300 DPI (or better) for photos, 1200 DPI for line art.

- Bleed included: trimming doesn’t cut off important design elements.

- Transparency handled properly: either flattened or preserved correctly, depending on the workflow.

- All content embedded: no external links that can break at the worst time.

What is PDF/X and Why Print Shops Require It

PDF/X is a subset of the broader PDF specification built specifically for professional printing. It removes any features that could cause printers to guess or “interpret” content differently.

Why PDF/X Exists

Normal PDFs are built for flexibility, which is great for documents that live on screens. But that flexibility can become a liability when the goal is consistent printing. A standard PDF might have a linked asset that suddenly goes missing, or a transparency effect that forces the RIP to make a decision you didn’t intend.

PDF/X basically says: No guessing. No surprises. Everything defined.

It requires full font embedding, correct color spaces, output intent profiles, and forbids interactive elements like form fields or videos. So when a PDF/X file reaches a print shop, they know exactly how the document should be printed with nothing left to interpretation.

When PDF/X is Expected

In professional settings like offset printing, packaging, magazine layouts, book production, and branded marketing materials, PDF/X is the default requirement. The cost of errors is too high to rely on files that “should be fine.”

In contrast, standard PDFs are great for digital docs, office printing, and collaboration workflows where perfect print fidelity isn’t the main objective.

PDF/X Standards: X-1a, X-3, and X-4 Explained

There isn’t just one PDF/X format — they evolved alongside printing technology.

PDF/X-1a: Most Compatible with CMYK-Only Printing

PDF/X-1a remains the most widely requested standard because it plays nicely with legacy systems and modern presses alike. It enforces CMYK-only color (plus spot colors), flattening transparency along the way. Everything in the file must be embedded, including fonts and images. This makes the file extremely predictable at every stage of print production, though transparency flattening may make files heavier and sometimes slightly alters blending appearance.

PDF/X-3: For Color-Managed Workflows

As printing workflows started adopting stronger color management, PDF/X-3 was introduced. It’s similar to X-1a but allows RGB and Lab color spaces as long as they include ICC profiles that tell the press how to interpret them. Many European workflows in particular rely on this standard.

Transparency flattening still applies, so the print shop still gets static objects but with more informative color handling.

PDF/X-4: Modern, Flexible, and Transparency-Friendly

PDF/X-4 is designed with modern digital presses and RIP systems in mind. Transparency stays live, layers are allowed, and device-independent color is supported with ICC profiles. This means:

- Smaller file sizes

- Faster rendering

- Visual effects preserved exactly as designed

Adoption has grown a lot in recent years, but if you’re unsure whether the print provider supports it, PDF/X-1a remains the “safe option.”

Choosing the Right PDF/X Standard

| Standard | Color Spaces | Transparency | Best For | Compatibility |

|---|---|---|---|---|

| PDF/X-1a:2001 | CMYK + spot only | Flattened | Maximum compatibility, traditional offset printing | Universal |

| PDF/X-3 | CMYK, spot, device-independent | Flattened | Color-managed workflows | Good |

| PDF/X-4 | CMYK, spot, device-independent | Native support | Modern digital printing, complex transparency | Modern systems |

Always confirm requirements with your print provider. When in doubt, PDF/X-1a offers the safest choice for compatibility, while PDF/X-4 provides advantages for modern digital workflows if supported.

How to Create Print-Ready PDF/X Files

Preparing a document for PDF/X isn’t something most designers want to think about every day. But a few fundamentals always matter:

- Work in the right color settings from the start

- Ensure images have high enough resolution

- Embed fonts (and be sure licenses allow it)

- Set trim and bleed properly in your layout

Then, during export, the software handles the heavy lifting converting colors, flattening transparency if needed, validating structure, and attaching the right ICC profile as output intent.

Manual PDF/X exports can be a bit intimidating because every piece needs to line up with specification rules. It’s why designers sometimes end up exporting multiple times (and sending multiple emails) before the print provider approves the file.

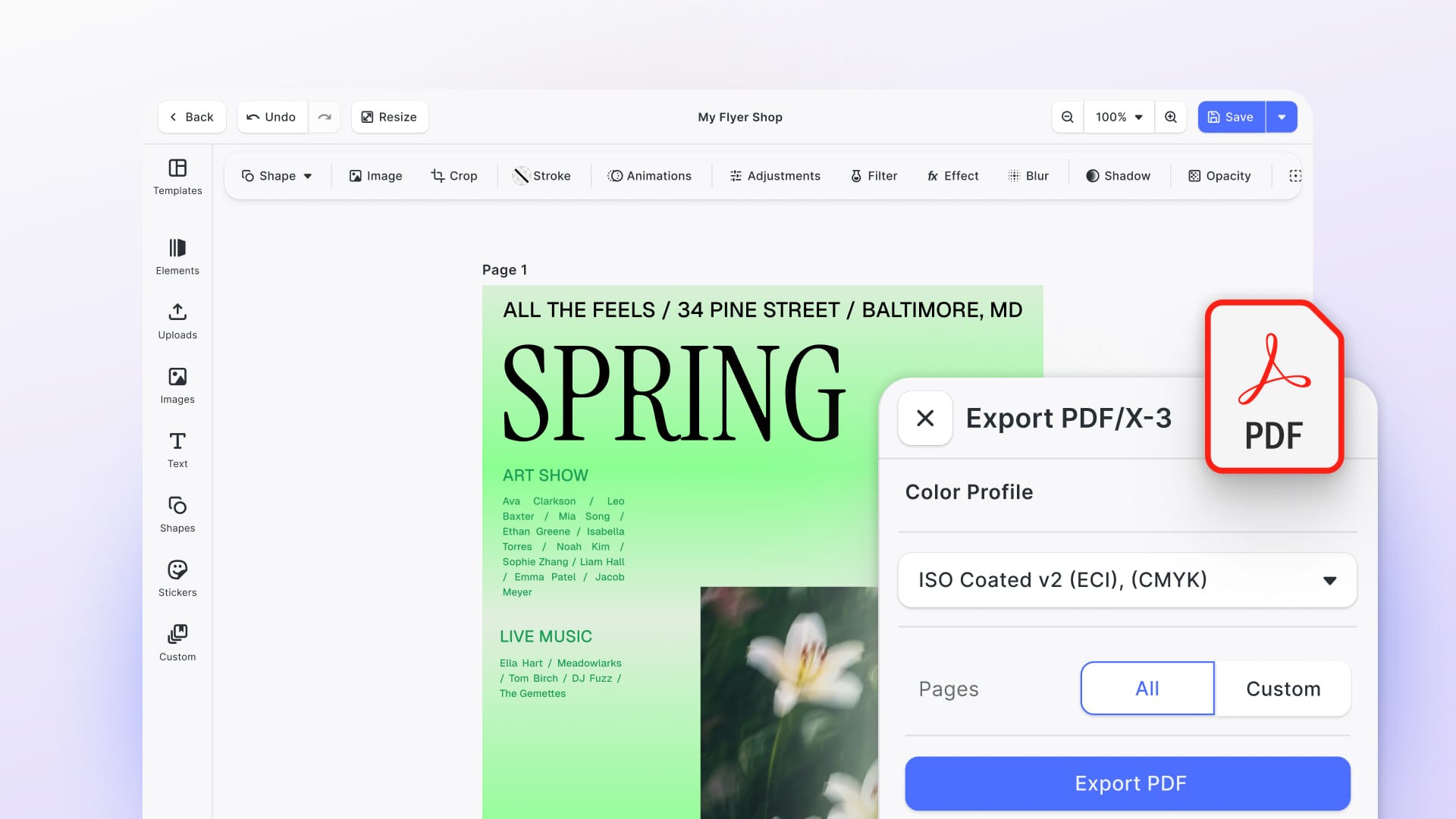

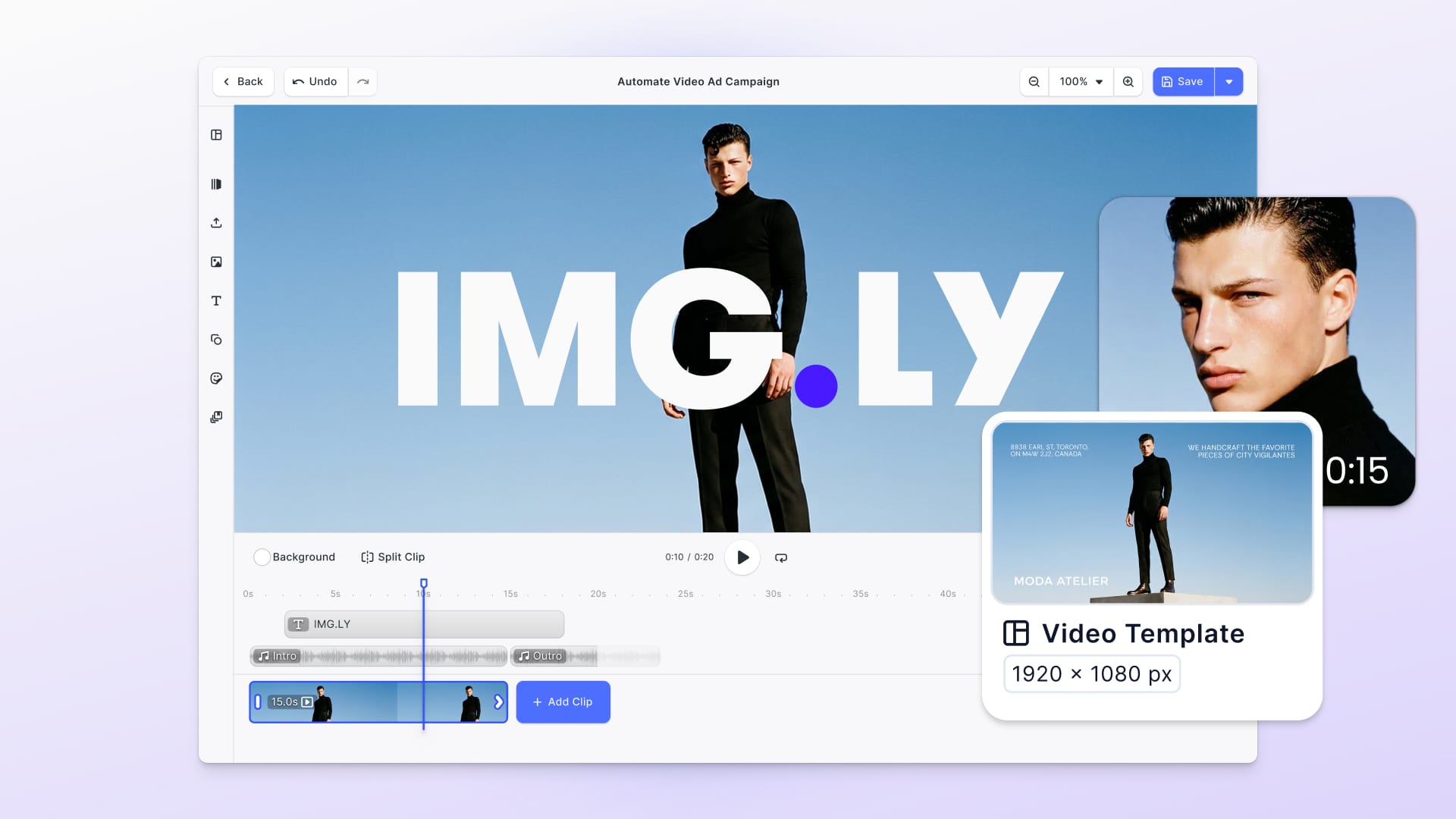

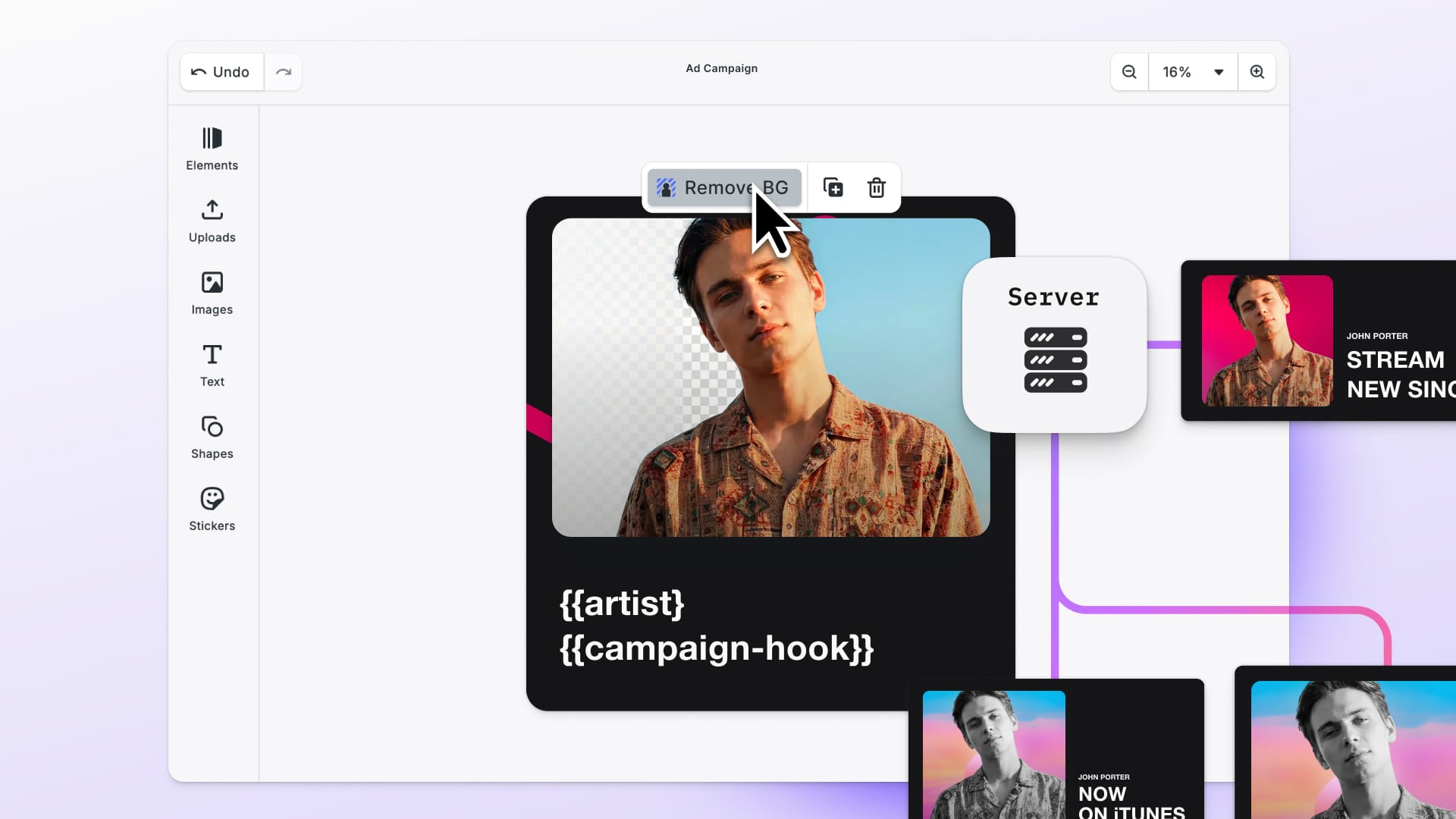

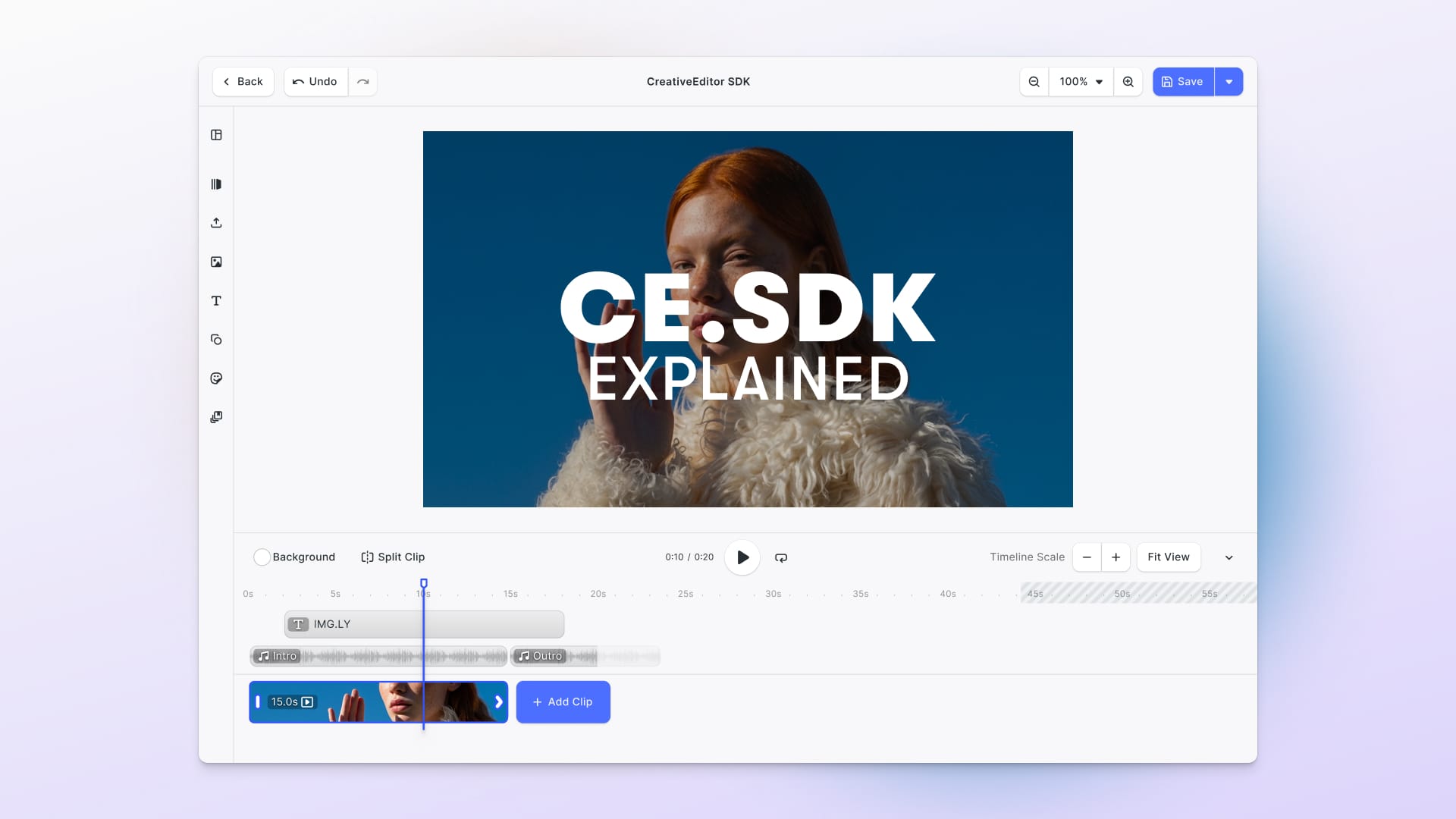

PDF/X Export with IMG.LY’s CreativeEditor SDK

The CreativeEditor SDK offers a dedicated Print-Ready PDF plugin that handles much of the complexity behind converting interactive or web-designed layouts into print-fit documents, so your team doesn’t need to become PDF or pre-press specialists.

The plugin supports workflows where you can generate print-ready files either in the editor UI or programmatically via code.

Out of the box, it can:

- Convert color spaces (e.g., from RGB to CMYK using ICC-profiles such as FOGRA39) to match commercial offset printing standards.

- Embed an output intent profile and set PDF-X compliance markers (for PDF/X-3:2003) so the exported PDF meets a recognized print standard.

- Handle transparency flattening when required (or allow you to disable it if transparency isn’t used) to ensure reliable print output.

- Enable streamlined export via JavaScript/Node or UI button, helping automate large-scale production workflows (print-on-demand, web-to-print, enterprise design platforms).

This makes it suitable for environments where you need to reliably generate thousands of output-files without needing dedicated pre-press steps.

PDF/X vs. Standard PDF: The TL;DR

| Aspect | Standard PDF | PDF/X |

|---|---|---|

| Color spaces | RGB, CMYK, Lab, device-independent | CMYK or device-independent colors with mandatory ICC output intent |

| Font embedding | Optional | Required (complete embedding) |

| Transparency | Native support | Transparency may be flattened to ensure reliable print processing |

| External content | Links permitted | All content must be embedded |

| Output intent | Optional | Required ICC profile specification |

| Interactive elements | Supported | Not permitted |

| Use case | General documents, screen viewing | Commercial printing, production workflows |

Standard PDFs are more flexible for general documents and screen use but for commercial printing you want a locked-down format: specifying color space, embedding all assets, disallowing interactive elements, and including an output intent. PDF/X ensures what you send is what prints, avoiding surprises or delays at the printer.

Bottom line: If you’re building a print-workflow where precision, repeatability and automation matter, pick PDF/X (and leverage CE.SDK’s print-ready plugin) over a generic PDF export.

Getting Started

If you're aiming for flawless print results right out of your app, the CreativeEditor SDK supports full PDF/X export. Easily test it in the interactive demo, dive into the docs, or just start a free trial and see how fast it fits into your print workflows. And if your process has unique production needs, our team’s happy to help, just reach out.

Frequently Asked Questions

What does PDF/X-1a mean?

PDF/X-1a is the most restrictive and universally supported PDF/X standard for professional printing. It requires CMYK and spot colors only (no RGB), complete font embedding, flattened transparency, defined trim and bleed boxes, and no external content references. This standard guarantees maximum compatibility with virtually all commercial printing equipment, making it the most commonly requested format by print shops.

What is the difference between PDF/X-1a and PDF/X-4?

PDF/X-1a requires CMYK-only colors and flattened transparency, ensuring maximum compatibility with all printing equipment including older systems. PDF/X-4 supports device-independent color spaces with ICC profiles and preserves native transparency without flattening, resulting in smaller file sizes and better quality for complex designs. PDF/X-4 works best with modern digital printing equipment, while PDF/X-1a remains the safer choice for universal compatibility.

Why do RGB colors cause problems in PDF/X-1a?

Commercial printing presses use CMYK (cyan, magenta, yellow, black) ink, not the RGB (red, green, blue) light-based color used by screens. PDF/X-1a prohibits RGB entirely because different systems convert RGB to CMYK differently, creating unpredictable color results. By requiring CMYK-only, PDF/X-1a gives designers explicit control over color conversion rather than leaving it to the print shop's systems, ensuring predictable and consistent color reproduction.

How do I fix font embedding errors?

Font embedding errors occur when fonts cannot be included in the PDF due to licensing restrictions or technical limitations. Verify font licensing permits embedding for commercial printing, replace restricted fonts with alternatives that allow embedding, and ensure the export system has access to complete font files, not just screen-optimized versions. For text converted to outlines, verify the conversion happened completely, as partially outlined text can cause validation errors.

What is transparency flattening and why does it matter?

Transparency flattening converts transparency effects (drop shadows, opacity changes, blend modes) into rasterized elements that can be reliably printed on any system. PDF/X-1a and X-3 require transparency flattening to ensure maximum compatibility. While flattening increases file size and can introduce visual artifacts in complex designs, it guarantees consistent reproduction across different printing equipment. PDF/X-4 preserves native transparency for modern systems that support it.

What resolution do images need for print?

Images need 300 DPI (dots per inch) at final print size for photographic content and color images. Line art should be 1200 DPI minimum. Screen-resolution images (72-96 DPI) appear pixelated when printed at commercial print resolution. Vector graphics avoid resolution issues entirely by scaling without quality loss, making them ideal for logos and illustrations.

What are bleed and trim boxes?

The trim box defines the final document size after cutting. The bleed box defines extended image areas beyond trim (typically 3mm or 0.125 inches on all sides) that account for slight variations in cutting precision. Bleed ensures design elements extend past trim edges, preventing white gaps if cutting is not perfectly precise. PDF/X files must include properly defined trim, bleed, and media boxes to pass preflight validation.

What is an output intent profile?

An output intent profile is an ICC color profile embedded in the PDF/X file that describes the intended printing condition. This profile tells the printing system how to interpret colors in the file. Common profiles include Coated FOGRA39 (ISO 12647-2:2004) for coated paper in Europe, GRACoL2006_Coated1v2 for coated paper in North America, and SWOP2006_Coated3v2 as an alternative North American standard. Always confirm the appropriate profile with your print provider.

How do I convert PDF to PDF/X-1a?

Converting existing PDFs to PDF/X-1a requires ensuring the file meets all compliance requirements: converting RGB colors to CMYK, embedding all fonts completely, flattening transparency effects, adding bleed and trim box definitions, specifying an output intent ICC profile, and embedding any linked external content. Professional PDF tools or SDKs with PDF/X export capabilities handle these conversions automatically, while manual conversion requires technical knowledge of PDF structure and color management.

Can I create PDF/X files without specialized software?

Creating compliant PDF/X files reliably requires software that understands PDF/X specifications and can handle color space conversion, font embedding validation, transparency flattening, and compliance checking. While some general PDF tools offer PDF/X export, they may not handle all compliance requirements correctly. Professional design applications (Adobe InDesign, Illustrator) include PDF/X export, or SDKs like IMG.LY's Creative Editor SDK provide integrated PDF/X capabilities for custom applications.

Do I need PDF/X for digital printing?

Most commercial digital printing operations require PDF/X files to ensure consistent, reliable production results. Digital printing equipment processes files more predictably when color spaces, fonts, and transparency are handled consistently through PDF/X compliance. Modern digital print shops often prefer PDF/X-4 for its native transparency support and efficiency, though PDF/X-1a remains widely accepted for maximum compatibility.

Can I edit a PDF/X file after export?

PDF/X files can be edited like any PDF, but modifications may break compliance. Editing colors, fonts, images, or transparency can introduce elements that violate PDF/X requirements. After editing, the file must be re-exported as PDF/X with full compliance validation to ensure it remains print-ready. Maintaining source files (InDesign documents, design files) for editing and exporting fresh PDF/X files for each revision is the recommended workflow.

How do I check if my PDF is PDF/X compliant?

Professional PDF applications include preflight tools that validate PDF/X compliance against standard requirements. These tools check color spaces, font embedding, transparency handling, bleed and trim definitions, output intent profiles, and other technical requirements. Adobe Acrobat Pro, PitStop, and Enfocus PitStop are common preflight tools. Many print shops also run preflight validation and will notify you of compliance failures before production.

What is a PDF/X converter?

A PDF/X converter is software that transforms standard PDFs or other file formats into compliant PDF/X files. Converters handle color space conversion, font embedding, transparency flattening, metadata insertion, and validation. However, conversion quality varies significantly between tools. Files designed for print from the beginning with proper color modes and fonts typically produce better PDF/X output than files converted after creation with incompatible settings.

Is PDF/X the same as PDF/A?

No. PDF/X is designed for commercial printing and enforces print-ready requirements like CMYK color and font embedding. PDF/A is designed for long-term archiving and enforces different requirements focused on preservation and self-contained documents. PDF/A files are not necessarily print-ready, and PDF/X files are not optimized for archiving. These are distinct standards serving different purposes.

Why is my PDF/X file larger than a standard PDF?

PDF/X files can be larger due to compliance requirements. Complete font embedding adds file size compared to partial subset embedding. Transparency flattening in PDF/X-1a significantly increases size for designs with complex transparency effects, as flattened areas become rasterized rather than remaining as compact vector data. However, PDF/X-4 files are often smaller than equivalent flattened X-1a files because native transparency preserves efficient vector representation. For print production, reliability matters more than optimizing for minimal file size.

Can PDF/X files contain images?

Yes. PDF/X files contain images just like standard PDFs, but images must meet specific requirements. For PDF/X-1a, images must use CMYK or grayscale color spaces (no RGB without conversion). Images must meet minimum resolution requirements (typically 300 DPI for photos). All images must be embedded, not linked externally. PDF/X-4 allows device-independent color spaces with proper ICC profiles, providing more flexibility for image color management.

What happens if I submit a non-compliant file to a print shop?

Print shops typically run preflight validation on submitted files. Non-compliant files will be rejected with a report detailing compliance failures—RGB colors in PDF/X-1a files, missing font embedding, insufficient image resolution, missing bleed definitions, etc. Production cannot proceed until files are corrected and resubmitted. This delays timelines and can incur additional fees for file preparation services if the print shop must fix issues. Submitting compliant PDF/X files from the beginning prevents these delays and costs.

No. PDF/X is designed for commercial printing and enforces print-ready requirements like CMYK color and font embedding. PDF/A is designed for long-term archiving and enforces different requirements focused on preservation and self-contained documents. PDF/A files are not necessarily print-ready, and PDF/X files are not optimized for archiving. These are distinct standards serving different purposes.

Why is my PDF/X file larger than a standard PDF?

PDF/X files can be larger due to compliance requirements. Complete font embedding adds file size compared to partial subset embedding. Transparency flattening in PDF/X-1a significantly increases size for designs with complex transparency effects, as flattened areas become rasterized rather than remaining as compact vector data. However, PDF/X-4 files are often smaller than equivalent flattened X-1a files because native transparency preserves efficient vector representation. For print production, reliability matters more than optimizing for minimal file size.

Can PDF/X files contain images?

Yes. PDF/X files contain images just like standard PDFs, but images must meet specific requirements. For PDF/X-1a, images must use CMYK or grayscale color spaces (no RGB without conversion). Images must meet minimum resolution requirements (typically 300 DPI for photos). All images must be embedded, not linked externally. PDF/X-4 allows device-independent color spaces with proper ICC profiles, providing more flexibility for image color management.

What happens if I submit a non-compliant file to a print shop?

Print shops typically run preflight validation on submitted files. Non-compliant files will be rejected with a report detailing compliance failures—RGB colors in PDF/X-1a files, missing font embedding, insufficient image resolution, missing bleed definitions, etc. Production cannot proceed until files are corrected and resubmitted. This delays timelines and can incur additional fees for file preparation services if the print shop must fix issues. Submitting compliant PDF/X files from the beginning prevents these delays and costs.